Passenger Elevator Series

for Modern Living and Working

Market demand is our direction of expansion. NBSL, with its insight into the market and its customers, closely focuses on the needs of its customers. From design, manufacturing, installation, and other aspects of performance optimization and resource reorganization, to provide customers with safer, more reliable, flexible, and efficient passenger elevator OEM series products, to build a better city life.

- Three sided safety frame protection, no fear of pressing or foreign objects getting stuck

- The utilization rate of the shaft is over 65%,and the top height of the small shaft is low, the depth of the bottom pit is shallow

- Adopting composite steel belt transmission, SIL3 level contacttess control technology, with operating noise less than 45 decibels

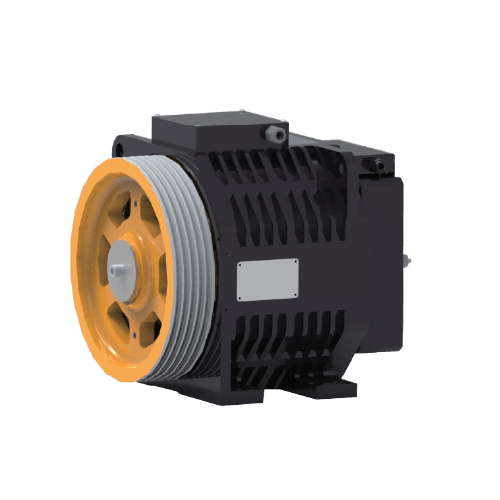

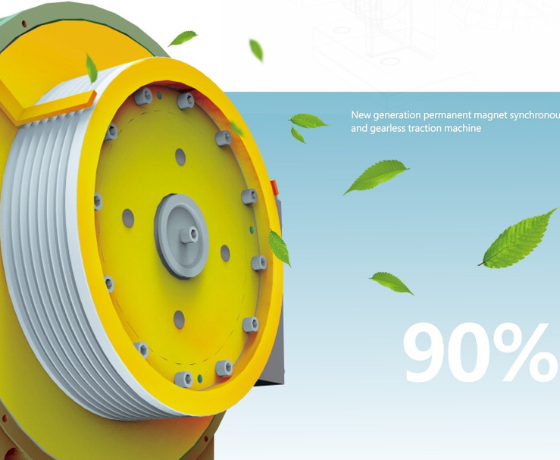

- Permanent magnet synchronous traction machine, vector frequency conversion control, green, energy-saving, and environmentally protection

Precise control, intelligent tech

Switching brake noise is 5-10 dB lower than traditional permanent magnet traction machine; Traction efficiency is over 90%; Small size and light weight, are about 50 ~ 70% of traditional asynchronous traction machine; Low energy consumption, which can save about 30-50% of electricity every year; Low temperature rise, maintenance-free and heavy load capacity; Suitable for products which loads up to 1600kg and speeds to 2.5m/s

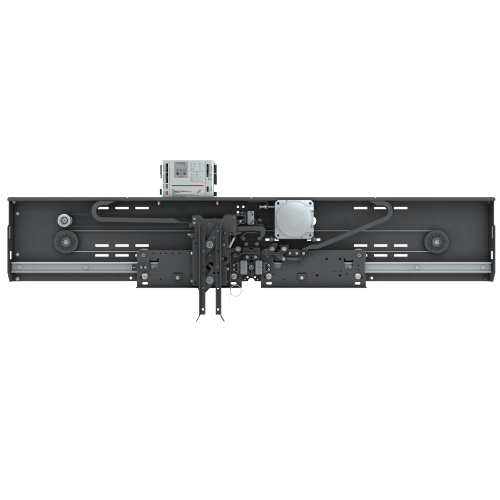

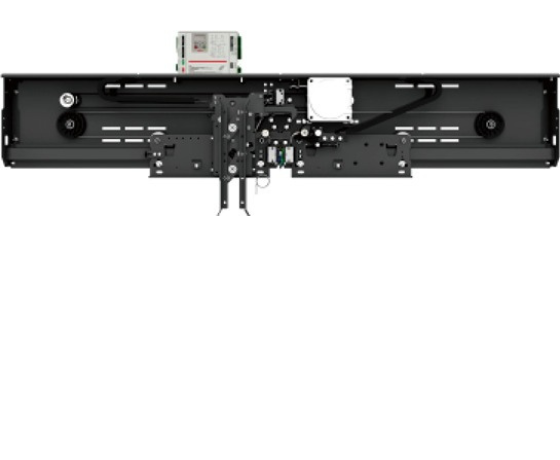

Safety&stable, smoothly opening

Good speed regulation characteristics, large starting torque and fast dynamic response; The system comes with door closing and running torque limit functions; Strong anti-electromagnetic interference ability; Simple structure, maintenance-free and low failure rate; Low noise, stable and reliable operation.

Environment-friendly, high efficiency and low energy consumption

Hardware and software fault-tolerant design to prevent accidents to the greatest extent; Galvanized material riveted cabinet without welding and painting, no environmental pollution; Compared with the traditional control cabinet, the height is reduced by 15CM, and the width is reduced by 7CM which is easy for installation.

Up & Down Building A Quality Life

- Controller IOT

-

Real-time monitoring of elevator running status, fault information, etc. In the event of a failure, an automatic background alarm is issued. The maintenance staff will know about it and goes to the site for treatment.

View historical data in the cloud to achieve full lifecycle monitoring and management. You can query the data of each operation of the control cabinet since it was powered on for the first time, and predict the devices that may fail according to the big data analysis of the operating conditions. - More extended functions

-

Establish an effective data file, which can view the maintenance situation in real time, and statistically view the overdue maintenance events, and at the same time support statistical analysis of elevator failure causes, maintenance, emergency repairs and other situations.

Wisdom Cloud also has extended functions such as face recognition, monitorin, gwarning, and maintenance recording. - Intelligent call system

-

Customers can use mobile phone client QR code, APP memory IC card to call the elevator, which is convenient and fast. While ensuring the safety allows authorized passengers to pass through smoothly.

- Intelligent sterilization system

-

Through intelligent ozone-free ultraviolet sterilization, sterilization is perfonmed in the unmanned car to ensure the safety of the riding environment.

- Door operator loT monitoring

-

Real-time viewing of various status and data of elevator door operators on mobile phones can effectively avoid poor communication and greatly improve the effect of remote guidance..

.

View historical data remotely to achieve full life cycle monitoring. You can query each action data of each door operator since it was first powered on.

.

Technical document query: According to the controller model, the fault code can directly query the troubleshooting method to facilitate maintenance personnel to work on site.

Precise control, intelligent tech

Switching brake noise is 5-10 dB lower than traditional permanent magnet traction machine; Traction efficiency is over 90%; Small size and light weight, are about 50 ~ 70% of traditional asynchronous traction machine; Low energy consumption, which can save about 30-50% of electricity every year; Low temperature rise, maintenance-free and heavy load capacity; Suitable for products which loads up to 1600kg and speeds to 2.5m/s

Environment-friendly, high efficiency and low energy consumption

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you coaHardware and software fault-tolerant design to prevent accidents to the greatest extent; Galvanized material riveted cabinet without welding and painting, no environmental pollution; Compared with the traditional control cabinet, the height is reduced by 15CM, and the width is reduced by 7CM which is easy for installation.mplete account of the system the actual teachings of the great explorer.

Safety&stable, smoothly opening

Good speed regulation characteristics, large starting torque and fast dynamic response; The system comes with door closing and running torque limit functions; Strong anti-electromagnetic interference ability; Simple structure, maintenance-free and low failure rate; Low noise, stable and reliable operation.

Consult Our Passenger Elevator Experts!

P300 MR Passenger Elevator (Rear acting) Layout

P300 MR Passenger Elevator (Side acting) Layout

P300 MR Panoramic Elevator Layout

P300L MRL Passenger Elevator Layout